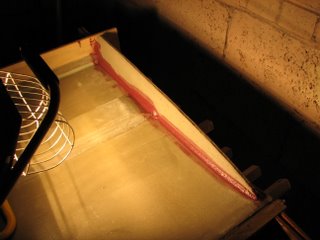

This shows how the forward beam bulkhead with the resin putty and tape was clamped into place while things were hardening. The bulkheads are aligned with form frame positions making it possible to use the strong back structure to clamp it into position.

My available work time on the boat is becoming increasing available after dark with the winter shorter days and all. So...work is getting darker and colder. The garage is not heated and I am finding without the heaters the epoxy will not completely harden. I am careful to keep the focused heat rotated around the part so that no distortions occur.

I have used probably a 50-50 combination of cabosil (better for adhesion) and microballoons (easy to fair) in my mix of putty for the bulkheads.

My trusty Zenon lamp that supplies heat and light.

1 comment:

Hi Grant,

Looks good! You are coming along well.

Something to watch out for is excess resin loss into the breather layer. If too much resin is drawn off then the laminate will be light but subject to failure with not enough resin transferring load between fibers. Use of a perforated release film will control resin loss, although may not draw off enough resin if far too much is used in laminating the fabric. This is a matter of being close with resin content during lamination. Weighing the dry glass and then the resultant finished part can be a good way to determine finished resin content. Anywhere around 40% resin by weight is a good target.

Also, watch using heat lamps for cure. They work well but can heat unevenly, causing excessive laminate distortion.

I'll have a look from time to time.

Post a Comment